Helical Gear Manufacturing Process . helical gears are manufactured using specific techniques, materials, and undergo quality control measures to ensure. Gears that have angled teeth in a helical pattern around the gear’s axis are known as helical gears. The accuracy needed in gear production poses significant challenges. Gear fabrication methods have been typically classified into three main categories: manufacturing helical gear involves several specialized techniques to accurately produce the angled teeth that characterize these gears. manufacturing process of helical gears. The hob and gear blank are rotated. Generation, forming, and form cutting. manufacturing helical gears is a complex process that demands precision and expertise. Taking into account the design,. hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. typical gear manufacturing processes.

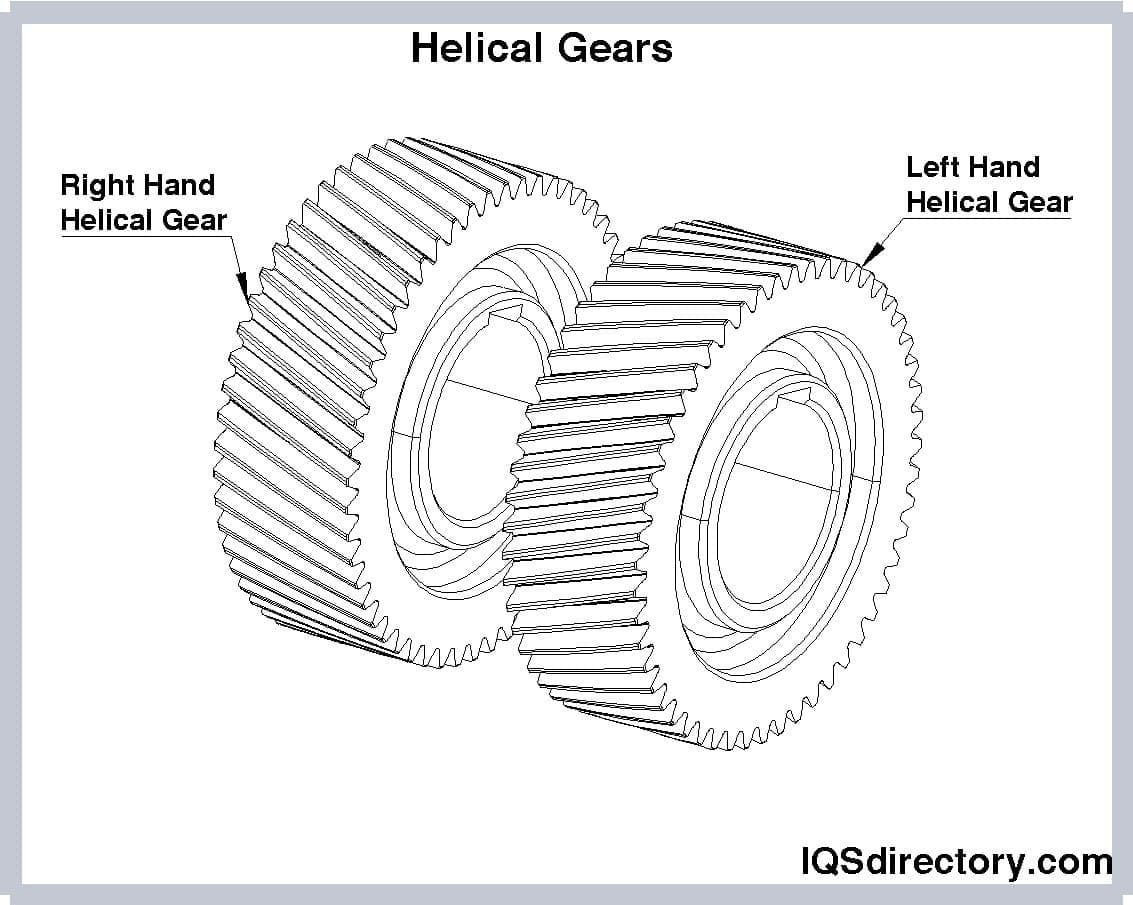

from www.iqsdirectory.com

The hob and gear blank are rotated. Gear fabrication methods have been typically classified into three main categories: The accuracy needed in gear production poses significant challenges. manufacturing helical gears is a complex process that demands precision and expertise. hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. typical gear manufacturing processes. manufacturing process of helical gears. helical gears are manufactured using specific techniques, materials, and undergo quality control measures to ensure. Taking into account the design,. Gears that have angled teeth in a helical pattern around the gear’s axis are known as helical gears.

Helical Gear What Are They? Types, Uses & Considerations

Helical Gear Manufacturing Process Generation, forming, and form cutting. Gear fabrication methods have been typically classified into three main categories: helical gears are manufactured using specific techniques, materials, and undergo quality control measures to ensure. The accuracy needed in gear production poses significant challenges. hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. manufacturing process of helical gears. Taking into account the design,. Generation, forming, and form cutting. manufacturing helical gear involves several specialized techniques to accurately produce the angled teeth that characterize these gears. Gears that have angled teeth in a helical pattern around the gear’s axis are known as helical gears. The hob and gear blank are rotated. typical gear manufacturing processes. manufacturing helical gears is a complex process that demands precision and expertise.

From www.zhygear.com

Understanding the Manufacturing Process of Spiral Bevel Gears ZHY Gear Helical Gear Manufacturing Process helical gears are manufactured using specific techniques, materials, and undergo quality control measures to ensure. The accuracy needed in gear production poses significant challenges. manufacturing helical gears is a complex process that demands precision and expertise. manufacturing process of helical gears. Gears that have angled teeth in a helical pattern around the gear’s axis are known as. Helical Gear Manufacturing Process.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations Helical Gear Manufacturing Process The hob and gear blank are rotated. Generation, forming, and form cutting. helical gears are manufactured using specific techniques, materials, and undergo quality control measures to ensure. hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. Gear fabrication methods have been typically classified into three. Helical Gear Manufacturing Process.

From extrudergearbox.net

Helical Gears Benefits and Manufacturing Process Helical Gear Manufacturing Process Gear fabrication methods have been typically classified into three main categories: The accuracy needed in gear production poses significant challenges. manufacturing process of helical gears. helical gears are manufactured using specific techniques, materials, and undergo quality control measures to ensure. Generation, forming, and form cutting. typical gear manufacturing processes. manufacturing helical gears is a complex process. Helical Gear Manufacturing Process.

From www.rapiddirect.com

Gear Manufacturing 101 A Comolete Guide on Gear Production Processes Helical Gear Manufacturing Process Gears that have angled teeth in a helical pattern around the gear’s axis are known as helical gears. helical gears are manufactured using specific techniques, materials, and undergo quality control measures to ensure. hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. manufacturing process. Helical Gear Manufacturing Process.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations Helical Gear Manufacturing Process manufacturing process of helical gears. The accuracy needed in gear production poses significant challenges. helical gears are manufactured using specific techniques, materials, and undergo quality control measures to ensure. Gear fabrication methods have been typically classified into three main categories: typical gear manufacturing processes. The hob and gear blank are rotated. Gears that have angled teeth in. Helical Gear Manufacturing Process.

From vestavia.eu

helical gear making Helical Gear Manufacturing Process hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. The hob and gear blank are rotated. Taking into account the design,. The accuracy needed in gear production poses significant challenges. typical gear manufacturing processes. helical gears are manufactured using specific techniques, materials, and undergo. Helical Gear Manufacturing Process.

From oggotech.com

Helical Gear Production, Gear Manufacturing Turkey OGGO Tech Helical Gear Manufacturing Process helical gears are manufactured using specific techniques, materials, and undergo quality control measures to ensure. The hob and gear blank are rotated. Generation, forming, and form cutting. Gear fabrication methods have been typically classified into three main categories: The accuracy needed in gear production poses significant challenges. manufacturing helical gear involves several specialized techniques to accurately produce the. Helical Gear Manufacturing Process.

From www.slideserve.com

PPT Comprehensive Guide to Precision Gear Manufacturing Processes PowerPoint Presentation ID Helical Gear Manufacturing Process The accuracy needed in gear production poses significant challenges. manufacturing helical gear involves several specialized techniques to accurately produce the angled teeth that characterize these gears. The hob and gear blank are rotated. Taking into account the design,. typical gear manufacturing processes. Generation, forming, and form cutting. manufacturing process of helical gears. Gear fabrication methods have been. Helical Gear Manufacturing Process.

From www.youtube.com

Amazing Helical Gear Manufacturing process YouTube Helical Gear Manufacturing Process The accuracy needed in gear production poses significant challenges. Gear fabrication methods have been typically classified into three main categories: manufacturing helical gear involves several specialized techniques to accurately produce the angled teeth that characterize these gears. helical gears are manufactured using specific techniques, materials, and undergo quality control measures to ensure. manufacturing helical gears is a. Helical Gear Manufacturing Process.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations Helical Gear Manufacturing Process hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. typical gear manufacturing processes. manufacturing process of helical gears. manufacturing helical gear involves several specialized techniques to accurately produce the angled teeth that characterize these gears. Generation, forming, and form cutting. helical gears. Helical Gear Manufacturing Process.

From www.youtube.com

Terminology of helical gear YouTube Helical Gear Manufacturing Process Gear fabrication methods have been typically classified into three main categories: hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. The accuracy needed in gear production poses significant challenges. manufacturing helical gears is a complex process that demands precision and expertise. manufacturing helical gear. Helical Gear Manufacturing Process.

From www.zhygear.com

Design of helical gear transmission based on MATLAB ZHY Gear Helical Gear Manufacturing Process Generation, forming, and form cutting. The hob and gear blank are rotated. helical gears are manufactured using specific techniques, materials, and undergo quality control measures to ensure. Gears that have angled teeth in a helical pattern around the gear’s axis are known as helical gears. Taking into account the design,. typical gear manufacturing processes. manufacturing helical gear. Helical Gear Manufacturing Process.

From khkgears.net

Gear Manufacturing KHK Gears Helical Gear Manufacturing Process Taking into account the design,. manufacturing process of helical gears. typical gear manufacturing processes. hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. helical gears are manufactured using specific techniques, materials, and undergo quality control measures to ensure. manufacturing helical gears is. Helical Gear Manufacturing Process.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations Helical Gear Manufacturing Process manufacturing process of helical gears. Taking into account the design,. The accuracy needed in gear production poses significant challenges. Gear fabrication methods have been typically classified into three main categories: The hob and gear blank are rotated. Gears that have angled teeth in a helical pattern around the gear’s axis are known as helical gears. hobbing is a. Helical Gear Manufacturing Process.

From www.youtube.com

Gear Manufacturing Process Gear Box Explained PPT ENGINEERING STUDY MATERIALS YouTube Helical Gear Manufacturing Process Gear fabrication methods have been typically classified into three main categories: manufacturing helical gears is a complex process that demands precision and expertise. helical gears are manufactured using specific techniques, materials, and undergo quality control measures to ensure. Taking into account the design,. manufacturing process of helical gears. manufacturing helical gear involves several specialized techniques to. Helical Gear Manufacturing Process.

From erkasmakine.com

Helical Gear ERKAS Makine ve Dişli Helical Gear Manufacturing Process Generation, forming, and form cutting. helical gears are manufactured using specific techniques, materials, and undergo quality control measures to ensure. The hob and gear blank are rotated. Taking into account the design,. typical gear manufacturing processes. hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting. Helical Gear Manufacturing Process.

From www.drivetrainhub.com

Helical Gears Geometry of helical gears and gear meshes Helical Gear Manufacturing Process Gears that have angled teeth in a helical pattern around the gear’s axis are known as helical gears. The accuracy needed in gear production poses significant challenges. Gear fabrication methods have been typically classified into three main categories: manufacturing helical gears is a complex process that demands precision and expertise. manufacturing helical gear involves several specialized techniques to. Helical Gear Manufacturing Process.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations Helical Gear Manufacturing Process helical gears are manufactured using specific techniques, materials, and undergo quality control measures to ensure. Gear fabrication methods have been typically classified into three main categories: manufacturing process of helical gears. hobbing is a gear manufacturing process in which gear teeth are generated through a series of cuts with a helical cutting tool. Generation, forming, and form. Helical Gear Manufacturing Process.